Injection Mould Tooling China: Revolutionizing Business at Hanking Mould

When it comes to injection mould tooling, Hanking Mould in China stands out as an industry leader. With their exceptional expertise and advanced manufacturing technologies, they have been revolutionizing businesses worldwide. From Acai Bowls to 3D Printing, their range of services caters to various industries and helps companies achieve new levels of success.

An Introduction to Injection Mould Tooling

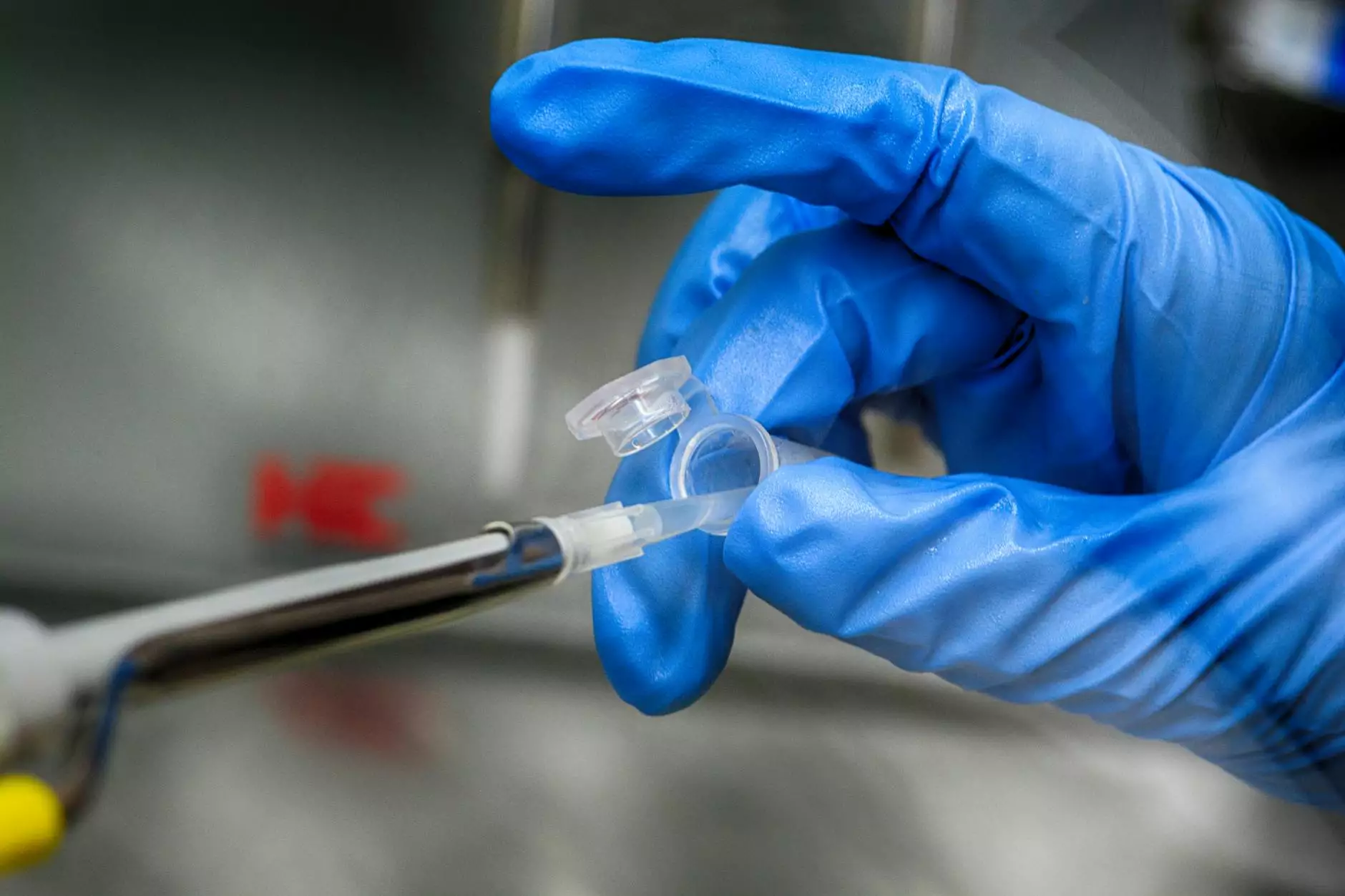

Injection mould tooling is a critical process in manufacturing plastic products. It involves creating precise and durable moulds that are used to shape molten plastic into desired forms. This process plays a vital role in industries such as automotive, electronics, consumer goods, and more.

Why Choose Hanking Mould?

Hanking Mould stands apart from its competitors due to its unwavering commitment to quality, extensive experience, and cutting-edge technology. Here are some key reasons why businesses worldwide trust Hanking Mould for their injection mould tooling needs:

1. Quality Manufacturing

When it comes to injection mould tooling, precision is of utmost importance. Hanking Mould excels in delivering high-quality moulds that meet the most stringent industry standards. Their attention to detail and rigorous quality control ensure that each product meets or exceeds customer expectations.

2. Advanced Technology

Hanking Mould stays at the forefront of technological advancements in injection mould tooling. They invest heavily in state-of-the-art machinery, software, and manufacturing techniques, enabling them to produce intricate and complex moulds with exceptional precision. Their commitment to staying updated with the latest industry trends allows them to provide innovative solutions to their clients.

3. Extensive Expertise

With decades of industry experience, Hanking Mould has developed extensive expertise in injection mould tooling. Their highly skilled team of engineers and technicians possesses in-depth knowledge of design principles, material characteristics, and manufacturing processes. This enables them to provide valuable insights and guidance to clients, ensuring optimal design and functionality of their products.

4. Customization Options

Hanking Mould understands that every client has unique requirements. They offer a wide range of customization options to tailor the injection mould tooling process according to specific needs. Whether it's material selection, surface finishes, or design modifications, Hanking Mould works closely with clients to ensure their vision is brought to life with precision and efficiency.

Acai Bowls: A Growing Trend

As the health and wellness industry continues to flourish, the popularity of Acai Bowls has skyrocketed. Acai Bowls are nutritious and delicious breakfast or snack options, featuring a base of Acai berries blended with various toppings such as fresh fruits, granola, and honey. Hanking Mould has been instrumental in supporting businesses in this growing sector by providing high-quality injection mould tooling services for the production of Acai Bowl containers.

3D Printing: Unleashing Imagination

3D Printing has emerged as a groundbreaking technology that revolutionizes manufacturing processes across industries. From prototyping to production, 3D Printing offers unparalleled design freedom and cost-efficient manufacturing solutions. Hanking Mould embraces 3D Printing as part of their comprehensive service offerings, enabling clients to bring their ideas to life rapidly and economically.

Conclusion

With its excellence in injection mould tooling and dedication to customer satisfaction, Hanking Mould continues to be the go-to choice for businesses seeking exceptional manufacturing solutions in China. Whether you are in the Acai Bowl or 3D Printing industry, Hanking Mould's expertise, advanced technology, and commitment to quality will propel your business to new heights. Trust Hanking Mould for all your injection mould tooling needs and experience the difference they can make.

injection mould tooling china