The Evolution of Road Cleaning Trucks through 3D Printing

Introduction

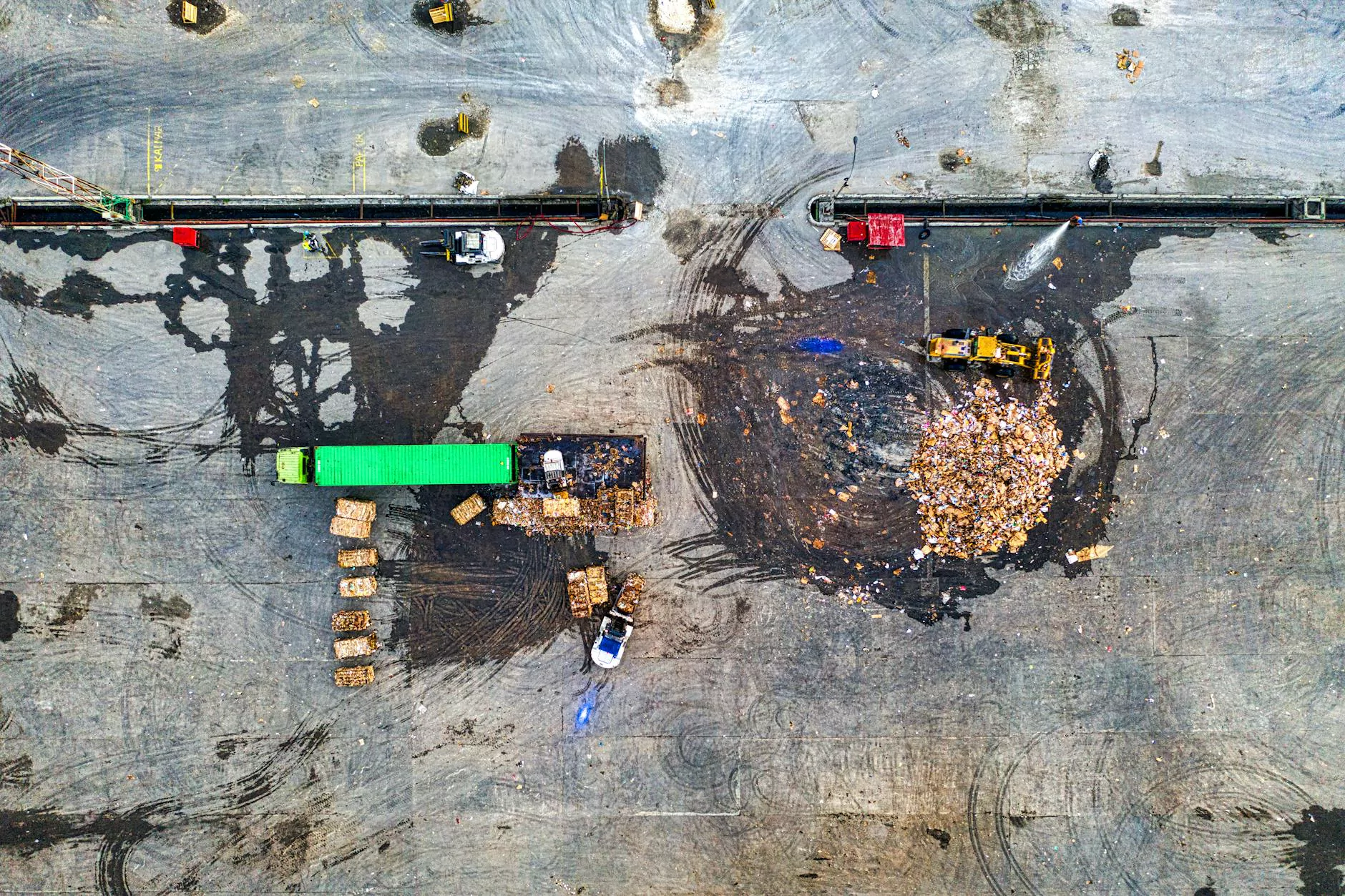

In the modern business landscape, innovation plays a crucial role in driving success and staying ahead of the competition. One area where innovation has truly transformed the way we do business is in the realm of road cleaning trucks. With advancements in 3D printing technology, these trucks have undergone a remarkable evolution, resulting in improved efficiency, durability, and customization. In this article, we will explore how 3D printing has revolutionized road cleaning trucks and the impact it has had on the industry.

The Power of 3D Printing

3D printing, also known as additive manufacturing, is a cutting-edge technology that enables the creation of three-dimensional objects layer by layer. This process has opened up a world of possibilities for various industries, including the manufacturing and automotive sectors. The efficiency and flexibility provided by 3D printing have paved the way for innovative improvements in road cleaning trucks.

Enhanced Efficiency and Performance

Road cleaning trucks are essential for maintaining clean and safe roadways. With the advent of 3D printing, manufacturers can now produce parts and components with superior precision and efficiency. This level of accuracy ensures optimal performance, minimizing downtime due to equipment failures. By creating intricate designs with 3D printing, the functionality and overall performance of road cleaning trucks have surged to new heights.

Durability and Customization

Traditional manufacturing processes often involve time-consuming and expensive tooling, which limits the ability to customize parts and components for road cleaning trucks. However, 3D printing has eliminated these barriers, allowing for the creation of highly durable and customized parts at a fraction of the cost. Manufacturers can now tailor each component according to specific requirements, resulting in road cleaning trucks that are perfectly engineered for their intended tasks.

Reduced Costs and Time-to-Market

One of the most notable advantages of 3D printing in the manufacturing industry is the significant reduction in costs and time-to-market. With traditional manufacturing methods, prototyping and production can be time-consuming and costly. However, 3D printing enables rapid prototyping and on-demand production, resulting in faster turnaround times and reduced expenses. Road cleaning truck manufacturers can now streamline their production process, making them more competitive and agile in the market.

Improved Sustainability and Environmental Conscientiousness

In today's world, sustainability is at the forefront of many business practices. 3D printing offers an eco-friendly alternative to traditional manufacturing methods. By using additive manufacturing, manufacturers can reduce material waste and energy consumption compared to conventional manufacturing techniques. This shift towards sustainability not only benefits the environment but also enhances the reputation and image of road cleaning truck manufacturers as responsible and environmentally conscious businesses.

Conclusion

The integration of 3D printing technology has revolutionized the road cleaning truck industry in numerous ways. From enhanced efficiency and performance to improved durability and customization, road cleaning trucks made with 3D printed components have surpassed traditional counterparts. Additionally, the reduced costs and time-to-market, as well as the sustainability benefits, make 3D printing an attractive option for road cleaning truck manufacturers. As the technology continues to advance, we can expect further innovations and advancements in the industry, driving even greater efficiency and productivity in road maintenance operations.