Boosting Your Business with High-Quality 3D Printing and Cost-Effective Die Casting Solutions

Introduction

Welcome to Quickparts.com, your go-to destination for high-quality 3D printing and cost-effective die casting solutions. In this article, we will explore the world of 3D printing and die casting and delve into the numerous benefits they offer to businesses of all sizes. Whether you are looking to prototype new products, optimize manufacturing processes, or streamline supply chain operations, Quickparts.com has you covered.

Why Choose Quickparts.com?

At Quickparts.com, we understand the importance of staying ahead in today's competitive business landscape. That's why we offer state-of-the-art 3D printing and die casting services that can help catapult your business towards success. Here are some key reasons why Quickparts.com should be your trusted partner:

Quality and Precision

When it comes to manufacturing, precision is paramount. Our team of experts at Quickparts.com ensures that every product we deliver meets the highest standards of quality and accuracy. Our cutting-edge 3D printing technology allows us to produce intricate designs with incredible detail, making it the perfect choice for even the most complex projects.

Cost-Effective Solutions

Running a successful business is all about optimizing costs without compromising on quality. With our die casting capabilities, we offer cost-effective solutions that can significantly reduce your manufacturing expenses. By leveraging this process, you can enjoy economies of scale, minimize material waste, and expedite production cycles, ultimately enhancing your bottom line.

Speed and Efficiency

In today's fast-paced world, time is of the essence. Quickparts.com understands this and provides rapid turnaround times, ensuring that your projects are delivered on schedule. Our advanced 3D printing and die casting technologies enable us to produce parts with unparalleled speed and efficiency, enabling you to meet deadlines and gain a competitive edge in your industry.

Unleashing the Power of 3D Printing

3D printing, also known as additive manufacturing, has become a game-changer in various industries. With this revolutionary technology, businesses can transform their ideas into physical reality quickly and cost-effectively. Let's dive into some key benefits of 3D printing:

Prototyping

Developing prototypes is an integral part of any product development cycle. Traditional prototyping methods can be time-consuming and costly, but with 3D printing, you can accelerate this process. By creating functional prototypes directly from your digital designs, you can test, iterate, and refine your products faster, leading to reduced time-to-market and enhanced customer satisfaction.

Customization

Personalization is increasingly becoming a key driver in consumer purchasing decisions. With 3D printing, you can offer highly customized products to cater to individual preferences. Whether it's creating bespoke jewelry, personalized phone cases, or tailor-made medical implants, the possibilities are limitless. This level of customization not only attracts customers but also strengthens brand loyalty.

Complex Geometries

Traditional manufacturing methods often struggle with producing parts with intricate geometries. 3D printing excels in this regard, as it allows for the creation of complex and organic shapes that were previously unattainable. This opens up new design possibilities and paves the way for innovative breakthroughs in industries such as aerospace, automotive, and healthcare.

Reduced Material Waste

Traditional subtractive manufacturing processes generate significant material waste. However, 3D printing follows an additive approach, where material is only used where it is needed. This leads to reduced material waste, resulting in cost savings and improved sustainability. Embracing 3D printing can help your business adopt more eco-friendly practices and contribute to a greener future.

Harnessing the Power of Die Casting

Die casting is a highly efficient manufacturing method that offers numerous advantages for businesses across various sectors. Here's why you should consider die casting for your production needs:

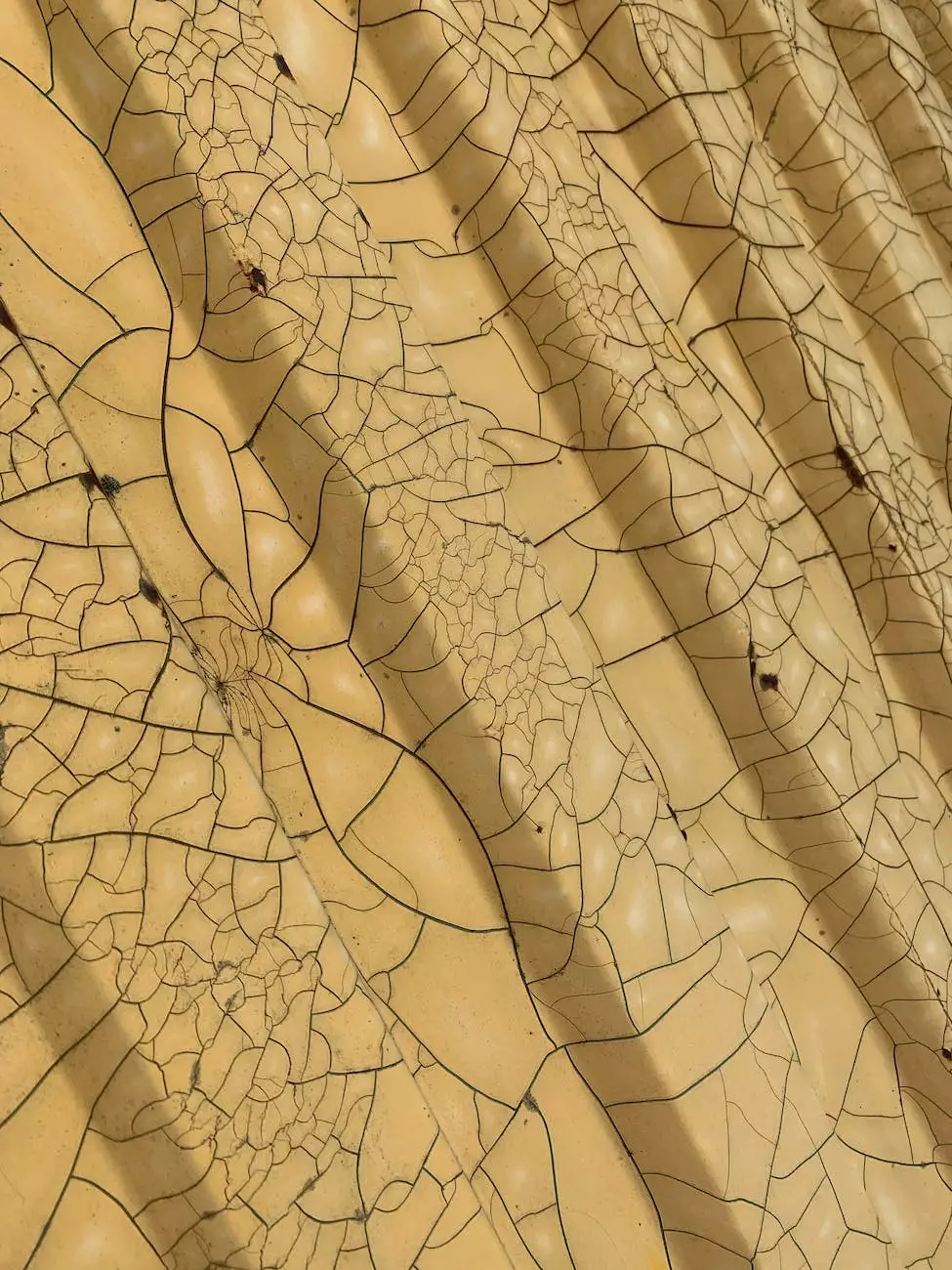

High Precision

Die casting enables the production of highly accurate and intricate parts with tight tolerances. This makes it an ideal choice for industries that require precision, such as automotive, aerospace, and electronics. The ability to consistently deliver high-quality components ensures that your end products meet the demanding standards of your customers.

Cost-Effective Mass Production

Die casting is exceptionally efficient for mass production. By using reusable molds, multiple identical parts can be cast in quick succession, reducing production costs per unit. The streamlined process allows you to scale up production and meet market demands without compromising on product quality or increasing your expenses.

Diverse Material Options

Die casting provides the flexibility of selecting from various materials, including aluminum, zinc, and magnesium alloys. Each material offers its unique properties, such as strength, durability, and heat resistance. This versatility allows you to choose the most suitable material for your specific application requirements to maximize product performance and longevity.

Reduced Assembly Needs

Die casting often produces complex parts that require minimal assembly. This leads to lower labor costs and quicker time-to-market. With fewer assembly steps, there is also a reduced chance of error, enhancing overall product quality and customer satisfaction.

Conclusion

Quickparts.com is your gateway to unlocking the immense potential of 3D printing and die casting technologies. By embracing these cutting-edge solutions, you can elevate your business to new heights of innovation, efficiency, and cost-effectiveness. With unwavering commitment to quality, precision, and customer satisfaction, Quickparts.com ensures that your manufacturing needs are met with excellence. Take charge of your business's success today and partner with Quickparts.com for all your 3D printing and die casting requirements!

die casting cost