The Lincoln Square Wave 200: The Pinnacle of Cutting and Welding Technology

In the fast-paced world of cutting and welding, having the right equipment is crucial for achieving exceptional results. The Lincoln Square Wave 200 stands out as a revolutionary machine that meets the diverse needs of both amateur and professional welders. This article delves into the intricate details of the Lincoln Square Wave 200, highlighting its features, advantages, and why it is the ideal choice for those in the cutting and welding sectors.

Understanding the Lincoln Square Wave 200

The Lincoln Square Wave 200 is a compact, lightweight welder designed to provide users with unparalleled control over their welding projects. Whether you are working on aluminum, stainless steel, or mild steel, this versatile machine allows for precise adjustments tailored to the specific needs of each material.

Key Features of the Lincoln Square Wave 200

- Multi-Process Capabilities: The Lincoln Square Wave 200 supports various welding processes, including TIG, Stick, and MIG welding. This flexibility makes it suitable for a wide range of applications.

- Easy-to-Use Interface: Equipped with an intuitive digital display, the Lincoln Square Wave 200 allows users to effortlessly adjust settings and monitor performance, ensuring optimal results.

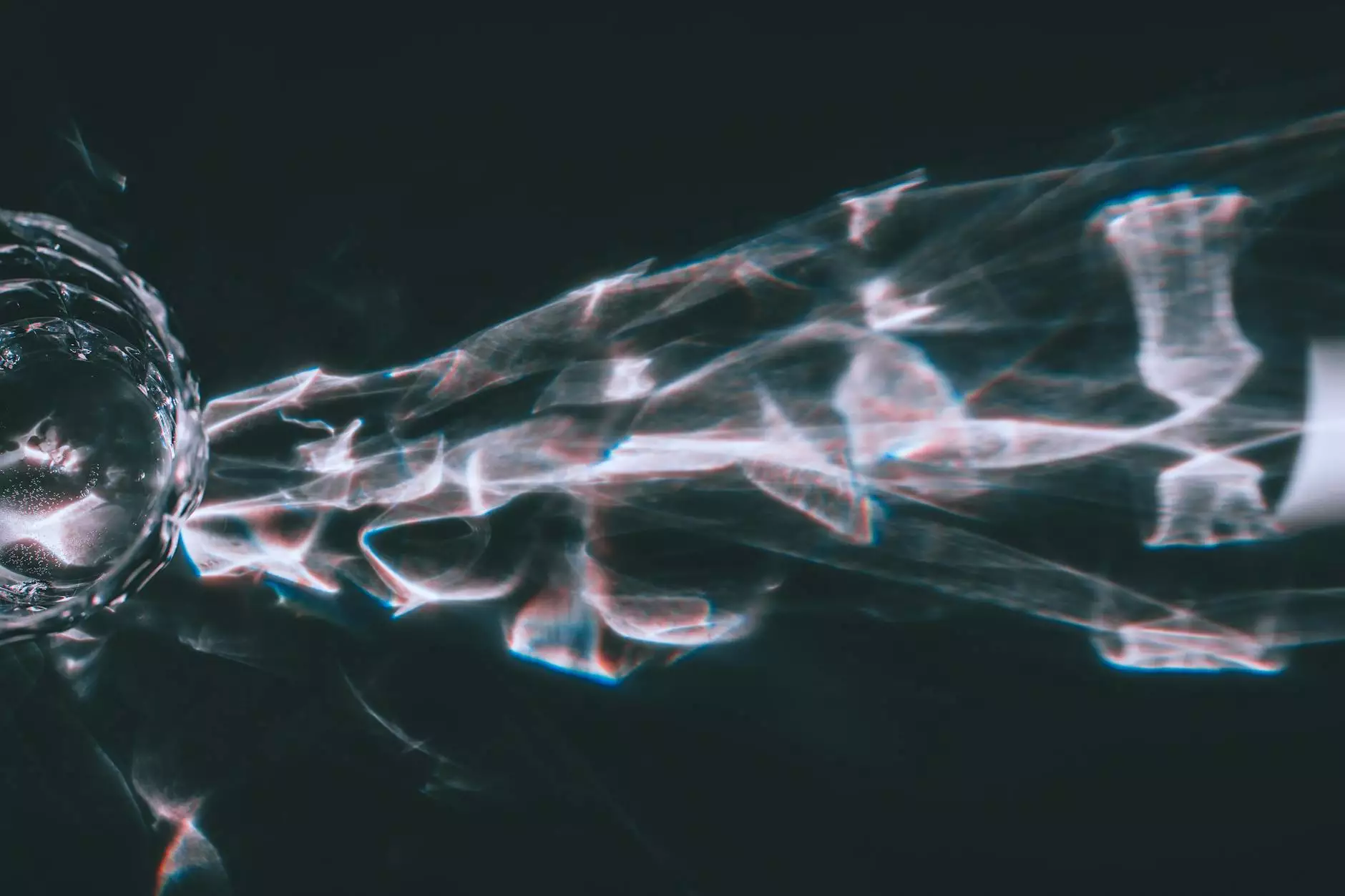

- Advanced Square Wave Technology: This unique technology enhances the arc stability and helix shape, resulting in improved bead appearance and penetration on aluminum materials.

- Portable Design: Weighing just around 40 pounds, the Lincoln Square Wave 200 is easy to transport. Its compact size makes it perfect for on-site jobs or small workshops where space is limited.

- Robust Build Quality: Designed to withstand the rigors of daily use, this welder is both durable and reliable, ensuring longevity in demanding work environments.

Benefits of Using the Lincoln Square Wave 200

Investing in the Lincoln Square Wave 200 offers numerous advantages for professionals in the cutting and welding industry. Here’s why this machine is a top choice:

1. Enhanced Precision and Control

The digital control panel allows users to set precise amperage levels, ensuring consistent and high-quality welds. This is particularly beneficial when welding thinner materials that require finesse.

2. Versatility Across Materials

The ability to weld aluminum, stainless steel, and mild steel makes the Lincoln Square Wave 200 an invaluable tool for fabricators and repair shops alike. The advanced square wave technology specifically optimizes the welding of aluminum, which can often be challenging with standard machines.

3. Fuel Efficiency

With rising energy costs, efficiency is a crucial factor. The Lincoln Square Wave 200 is designed to provide powerful welding capabilities while consuming less electricity, making it a cost-effective solution for businesses.

4. Safety Features

Safety is paramount in welding. This model incorporates several protective features, such as thermal overload protection, ensuring that the machine remains safe and operational even under heavy use.

Applications of the Lincoln Square Wave 200

The versatility of the Lincoln Square Wave 200 makes it suitable for a broad array of applications:

- Automotive Repairs: Ideal for TIG welding on aluminum bodywork or stainless steel exhaust systems.

- Artistic Metalwork: Perfect for artists and fabricators who require precise welding for intricate designs.

- Maintenance and Repairs: The perfect companion for professionals in the maintenance field needing a reliable, quick, and efficient welding solution.

- Small Fabrication Shops: The Lincoln Square Wave 200 is ideal for small operations that require versatility and quality without sacrificing space or budget.

Customer Experience with the Lincoln Square Wave 200

Customer satisfaction is a key indicator of a product’s quality and reliability. Users of the Lincoln Square Wave 200 consistently report high levels of satisfaction due to its performance and user-friendly features.

Many reviews note the machine's excellent arc stability, which contributes to superior bead quality. The lightweight design is also a significant plus for professionals who travel to job sites, as portability enables quick setups without hassle.

Comparison with Other Welders

When comparing the Lincoln Square Wave 200 to other welders on the market, it holds its ground exceptionally well due to its unique features and capabilities. Below are a few noteworthy competitors:

- Miller Maxstar 150: While also portable, it falls short in terms of dual-capability (AC and DC) that the Lincoln provides.

- Thermal Arc 161S: While cost-effective, it does not match the advanced features and technology of the Lincoln Square Wave 200.

- Everlast PowerTIG 200DV: Although it has compelling features, many users prefer the ease of use and quality of welds produced by the Lincoln.

How to Maximize the Performance of the Lincoln Square Wave 200

To get the most out of your Lincoln Square Wave 200, consider the following tips:

1. Understand Material Requirements

Different materials require different settings and techniques. Take the time to adjust the machine for optimal performance based on the type of metal you are working with.

2. Regular Maintenance

Keeping the machine clean and performing regular maintenance checks will ensure it runs smoothly and lasts longer.

3. Invest in Quality Consumables

Using high-quality filler rods and electrodes can significantly improve the quality of your welds and the durability of your projects.

4. Continuous Learning

Stay updated on welding techniques and practices. Attend workshops or engage with online communities to learn from experienced professionals.

Conclusion

In conclusion, the Lincoln Square Wave 200 is a powerful and versatile tool that meets the demands of modern welding applications. Its innovative technology, user-friendly design, and adaptability to different welding techniques make it an excellent investment for both professionals and enthusiasts in the cutting and welding industry.

Whether you are running a small fabrication shop, working in automotive repairs, or producing artistic metalworks, the Lincoln Square Wave 200 is equipped to handle all your welding requirements with precision and efficiency. With its ability to provide high-quality welds consistently, it's no wonder that this machine is rapidly becoming a favorite among welders everywhere.