The Power of Business and 3D Printing: Understanding PBF Technology

In today's rapidly evolving landscape, business innovation is at the forefront of successful operations. One of the most fascinating advancements in technology is 3D printing, which has revolutionized how businesses create, design, and manufacture products. Among various techniques in 3D printing, PBF (Powder Bed Fusion) stands out as a remarkable method that enhances efficiency, customization, and production capabilities.

What is PBF Technology?

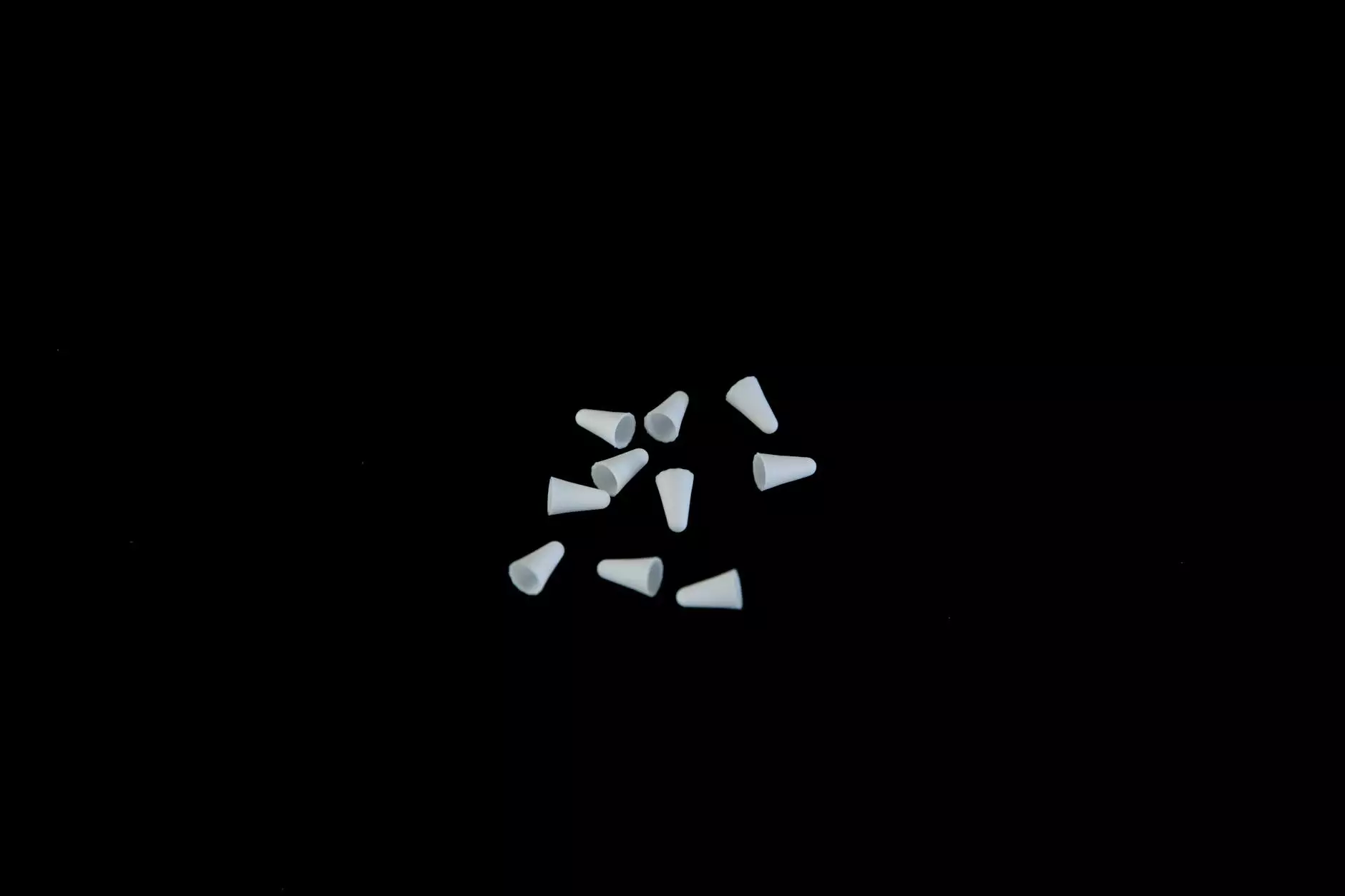

PBF or Powder Bed Fusion is a 3D printing technology that utilizes powdered materials to create solid objects through a series of layers. This process involves selective laser sintering or melting powdered materials with an energy source, typically a laser, that fuses the particles together. The result is a highly detailed, accurate, and complex object. Let’s delve deeper into how PBF works.

How PBF Works

The PBF process can be broken down into several key stages:

- Preparation of the Print Bed: A thin layer of powder is spread evenly across the print bed.

- Laser Activation: The laser scans the surface of the powder, fusing specific areas where solidification is required.

- Layering: Once a layer is complete, another layer of powder is applied, and the process repeats.

- Cooling: The print is allowed to cool before being extracted from the powder bed.

This iterative layering technique allows for the production of intricate designs and geometries that are often impossible to achieve with traditional manufacturing methods.

The Business Benefits of PBF Technology

PBF technology isn’t just a fascinating engineering feat; it offers a plethora of business advantages:

1. Cost Efficiency

Businesses adopting PBF technology enjoy reduced costs in material waste. Unlike traditional subtractive manufacturing methods, where excess material is discarded, PBF only uses the required amount of powder, minimizing waste significantly.

2. Rapid Prototyping

PBF enables faster prototyping cycles. Companies can go from ideas to tangible objects in a fraction of the time than with conventional methods. This rapid turn-around helps businesses stay ahead of competitors.

3. Design Flexibility

With PBF, engineers and designers can create highly complex geometries that were previously unimaginable. This flexibility allows for innovative designs that enhance product functionality and aesthetic appeal.

4. Customization

In a market that increasingly demands personalized products, PBF allows businesses to offer customized solutions. This ability to tailor products to individual customer specifications can significantly enhance consumer satisfaction.

5. Sustainability

As businesses worldwide seek to enhance their sustainability initiatives, PBF stands out as an eco-friendly option. The process minimizes waste and can utilize recyclable materials, contributing to a reduced environmental footprint.

Industries Transforming with PBF

Various sectors are experiencing transformational benefits from the adoption of Powder Bed Fusion technology:

Aerospace

The aerospace industry is one of the early adopters of PBF technology. This method allows for the creation of lightweight yet strong components that are crucial for improving fuel efficiency and aircraft performance.

Automotive

In the automotive realm, PBF is revolutionizing manufacturing by enabling the production of complex parts with reduced weight. This not only enhances vehicle performance but also promotes manufacturing efficiency.

Healthcare

PBF has made significant inroads into healthcare, especially in creating custom implants and prosthetics tailored to individual patient anatomy. The precise nature of PBF allows for better fitting and improved outcomes for patients.

Consumer Goods

From custom phone cases to personalized utensils, consumer goods companies leverage PBF to provide unique products that resonate with individual customer preferences.

Challenges and Considerations in PBF Implementation

While the benefits of PBF technology are substantial, several challenges need consideration before implementation:

1. Initial Investment

The upfront investment for PBF equipment can be significant. Businesses need to evaluate the cost-benefit ratio carefully to justify the expenditure.

2. Material Limitations

Currently, PBF is limited to specific materials, chiefly metals and certain polymers. Business sectors that require a broader range of materials may find this a limitation.

3. Technical Expertise

To operate PBF machines effectively, businesses need skilled personnel trained in operating and maintaining these sophisticated machines. This can pose a challenge for companies lacking in-house expertise.

Future of PBF in Business

The future of PBF technology in business looks promising. With continuous advancements in materials science and 3D printing technology, businesses can expect further enhancements in the speed, efficiency, and quality of production.

Moreover, as more industries recognize the benefits of 3D printing, the integration of PBF technology is likely to become a standard practice, making it essential for companies to adapt and innovate.

Conclusion: Embrace the PBF Revolution

In conclusion, Powder Bed Fusion technology is not just a fleeting trend in 3D printing; it’s a powerful tool that businesses can leverage to enhance efficiency, reduce costs, and improve product offerings. By embracing the PBF revolution, companies can position themselves at the forefront of innovation, ready to capture the opportunities presented by this transformative technology.

For businesses looking to explore the advantages of 3D printing and PBF, it is vital to partner with experts who can guide them through the technology's intricacies and benefits. At Infotron, we are dedicated to helping businesses harness the power of 3D printing to drive their success.